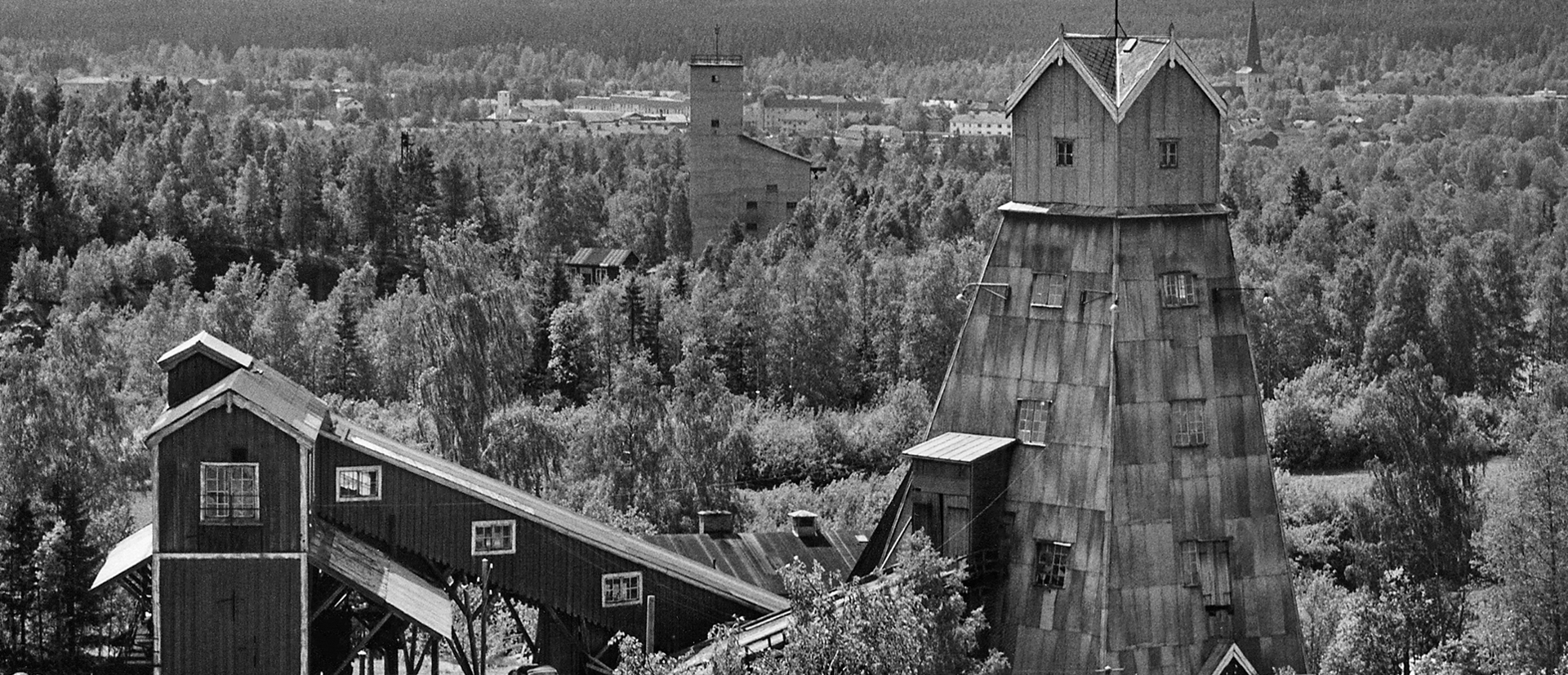

Photo: Pål-Nils Nilsson / Riksantikvarieämbetet

From simple hoes to automated processes, from drafty sheds to robust cities, the journey to the current-day modernity of Swedish mining has been a long and – at times – difficult one, but it has paid off in the form of welcome prosperity and economic stability. The role of mining companies has been crucial for both regional and national prosperity.

Our pursuit to explore deep deposits using efficient and sustainable methods has resulted in many revolutionary innovations, from the world’s oldest blast furnace to 3D visualization of underground mines. Along with steel and metal works, mining has now come to make up a large part of Sweden’s export industry.

The business developed through large and expensive investments in these innovations; it is sometimes said that the world’s oldest joint-stock company was formed at the copper mountain in Falun in the 1300s. From the mid-1200s until the late 1800s, Sweden went through long periods of being the world leader in iron production. During Sweden’s reign in the 1600s, Falun Mine accounted for 2/3 of the world’s copper production, and by the mid-1700s, iron made up about 70% of Sweden’s total exports.

As new discoveries were made, just as demand on the European market spiked, ore extraction was strongly supported by the nation’s leadership and assumed a greater importance economically and politically for the country. At a time when 25% of Swedes were immigrating to America in an attempt to avoid starvation and poverty, the need for this new future was apparent. The opportunities presented by the country’s iron ore deposits convinced investors and politicians to make courageous decisions based on visionary ideas, including the first step in creating an advanced and modern infrastructure—building the Iron Ore Line.

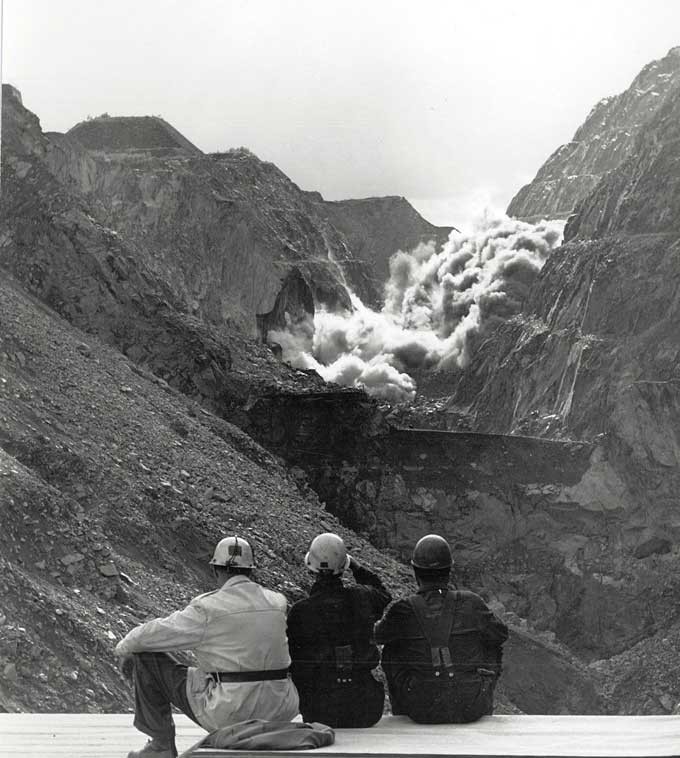

Photo: G Rúnar Gudmundsson

On March 12, 1888, the first ore car reached the new iron port of Luleå from the ore mountain in Gällivare. The mineral company LKAB was formed in 1890 and 14 years later LKAB’s entire mining operation was linked to the global market by rail, from Luleå in the south to the port of Narvik in the north. Demand for iron was enormous in Europe, and the railway gave Swedish mines a road to grow from small-scale operations to large-scale production. The export of Swedish iron ore paved the way for Sweden’s integration into Europe. It gave the country a renewed financial structure and contributed to the emergence of modern Sweden.

Another crucial factor in the country’s success was the hard work and unwavering innovative spirit of its people, which enabled an increase in production rate despite mining to ever deeper levels. Towards the end of the 1910s, there were nearly 500 mines in Sweden that produced a total of 8.8 billion tons of ore. Just 50 years later, the number had fallen to 100 mines, but ore production had increased to 22 billion tons. Increased mechanization had improved working conditions and profitability of many mines, but smaller mines that couldn’t afford the investments were forced to shut down. The Boliden Mine, Europe’s largest and richest gold mine, shut down in 1967, and Falun’s copper mine shut down in 1992 after 1,000 years of operation.

“One who does well at suffering will also do well at winning. A struggle for survival forced innovations in the 80s and 90s. Innovations that came about because there were people who had the courage to implement them.”

Per-Erik Lindvall, Brexia Business AB.

Photo: LKAB

Today, Swedish mining is a high-tech industry in the truest sense of the word, as well as a driving force for new innovations in everything from engineering products and environmental tech to energy efficiency. Sweden ranks second in the global environmental regulation index; the focus of the mining industry is currently on lowering carbon emissions, increasing safety, and last but not least, recycling. Sweden has 16 mines in operation (2015) and is currently, by far, the largest producer of iron ore in Europe. The country also is one of the foremost producers of base metals and precious materials.

The mining industry provides great social benefits for the entire country in the form of revenue from exports, a large number of jobs, and tech-driven development that spreads to other industries. For hundreds of years, companies as well as entire communities have been forming in the areas around particularly rich iron deposits and other metal deposits. By its very nature, a mining company cannot move, which is why sustainable development throughout all aspects of the company as well as building a strong connection to the local community are crucial to long-term operation. Kiruna is the most well-known example, where the city is now being moved in order to ensure a future for the world’s largest underground iron ore mine, thousands of jobs for local citizens, and the possibility of sustainably providing the rest of the world with necessary minerals.

To be continued…